Client

Location: Niemegk, Germany

Completion date: 2021

Artwork budget: $38,000

Project Team

Head of Company

Rainer Rogovits

ENVIRAL® Oberflächenveredelung GmbH

artists

Various & Gould

Overview

A powder-coated metal facade-installation as commission for the 25th anniversary of the company Enviral.

With the company’s own technology and in close cooperation with the employees, Various & Gould have realized a relief like wall-installation on the premises of the factory. The result is ‘Farbstrahlen’ – their first public metal installation. The starting point was a small paper collage with elements from previous works. This artwork marks the beginning of a new series called Interval. The color rays have the impression of paper, with all it’s wrinkles and folds.

Dimensions: 30 m2 (ca. 324 square foot)

A collage-sketch of 500 grams of paper turned into about 500 kg of metal.

Goals

It all started with an anniversary and we were asked to represent the companies work field on the outside facade.

We were able to find a sort of abstract translation of the companies working field by addressing the sensual perception of color and color processing.

By slightly staggering the levels, the shadow cast within the installation changes, depending on the position of the sun. From the technical side the installation shows a wide range of possible applications and effects of powder-coating from glossy to matt and incorporated stencil work. This work is permanently installed and freely accessible on the companies premises.

Process

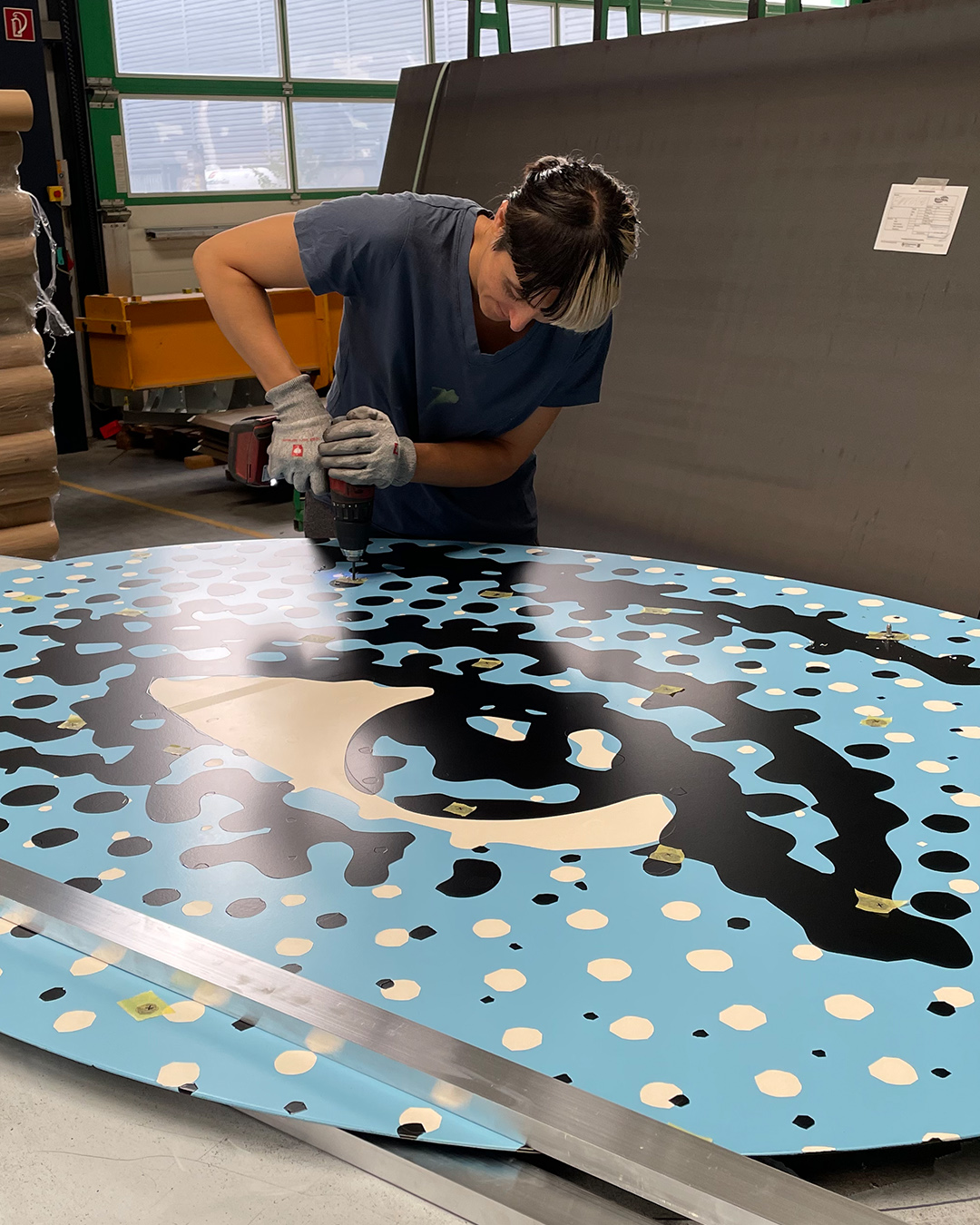

The owner of the company had asked us to paint a mural on the outside of the powder tower, which is all corrugated metal. When we visited the site, we asked, if it wouldn't be more suitable to use the companies own special technique of large-scale powder coating. He agreed, as the company has had some previous experience with small artists collaborations.

From there we developed a collaged-sketch and some digital sketches. We were able to win him for the most bold and abstract one. He even suggested to go dimensional and work with relief. From there we went on and it was a very fruitful, but also challenging process, as some metal sheets were unavailable due to the Corona related supply shortages and higher prices and we hadn’t anticipated the static requirements.

The powder coated aluminum sheets needed to be riveted on a self-manufactured steel frame. Luckily welding and steel work was also part of the skills within the company, especially one of the workers who was assigned to the project, was very experienced. In the end the massive frame got lifted with a crane and the whole artwork got attached onto hooks onto the facade.